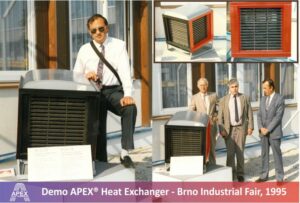

Company History

APEX Group established itself as an important stakeholder in the energy recovery industry due to our founder’s groundbreaking advancements in plate-type heat exchanger technology. Since then – and built upon 50+ years of experience and expertise – APEX Group has continued to maintain its prestigious reputation by expanding our range of high-quality heat exchanger products.

How it all started?

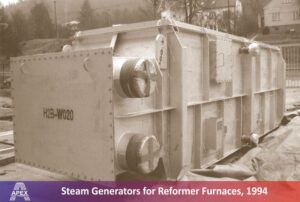

In the early days of Mircea Dinulescu’s career as a heat-transfer engineer, he frequently worked with the Air Preheaters used in petrochemical and power plant heaters. In those days, Air Preheaters were constructed out of heavy cast-iron tubular elements. According to Mircea, the design was not optimal for the intended application. Therefore, he conducted a theoretical analysis and concluded that a higher performance and lower price could be achieved through the use of a new plate-type design. In order to prove this theory, he issued a number of patents and incorporated APEX Group with the purpose of bringing his design onto the market.

How is it going?

In the present day, the market for Air Preheaters is dominated by plate-type heat exchangers invented by Mircea. Yet, since this innovation, neither Mircea nor APEX Group have remained stagnant.

As of today, APEX Group has:

- delivered over 2500 heat exchangers to over 100 countries;

- executed over 1400 projects for more than 900 customers and end-users; and

- established multiple technical and manufacturing facilities across Europe.

A look into the future.

Going forward, APEX Group will continue to be guided by its clear vision. This has been, since the beginning of 1991, that APEX Group will “grow into a reputable designer and manufacturer of high quality, low-priced industrial heat transfer and combustion equipment for the international market” (M. Dinulescu, 1991).

To abide by this guiding principle, APEX Group will continue to improve heat exchanger technologies and work to incorporate the benefits of digitization. It is clear that heat exchange technologies will play an important role as we move towards decarbonization; heat exchangers decrease operational costs and greenhouse gas emissions in energy-intensive industries. However, we are also committed to incorporating the benefits of heat exchangers into emerging technologies such as carbon capture and storage (CCS).