APEX Group’s Research and Development team proudly presents our latest innovation in Heavy Duty Heat Exchangers: APEX-delfino® Technology. The new technology optimizes flow distribution and influences turbulence for improved operation of Free-flow™ Plate-type Heat Exchangers.

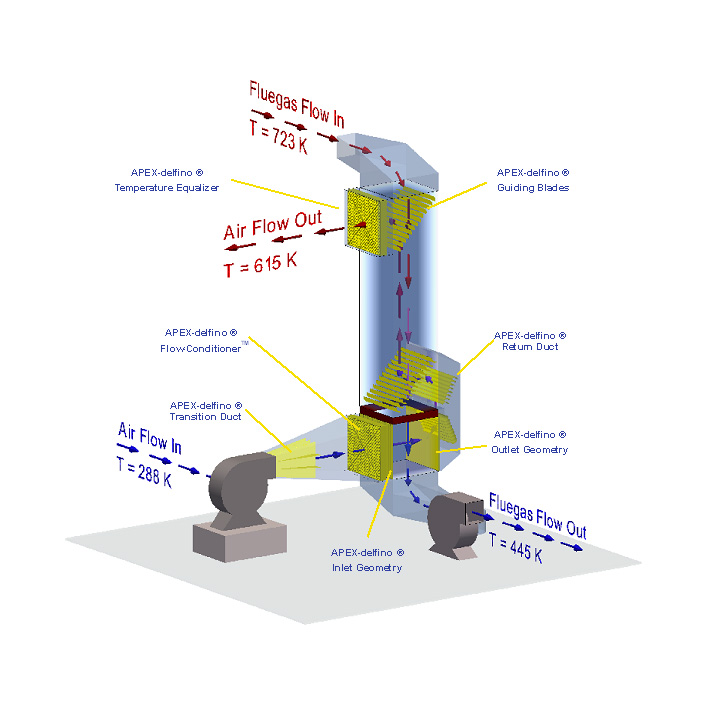

Large amounts of hot Fluegas and Air are guided through the tailored Plate-type Heat Exchanger. The volume flow rates can easily exceed 2,000,000 kg/h. The flow is guided in complex flow paths through the modular units such as pure cross-flow or countercurrent flow arrangement at even low Reynolds number with increased heat transfer.

APEX-delfino® increases the effectiveness and the lifetime of the unit, thanks to corrosion protection, easy-access cleaning and reduced pressure drop at high heat transfer rates. APEX-delfino® Technology achieves a streamlined and uniform flow closely matching the ideal flow field characteristics with no flow separation.

APEX-delfino® Technology is an agglomeration of improvements along the path of a fluid element, which is travelling through the Heat Exchanger starting at the centrifugal fan. Amongst others, the APEX-delfino® Flow Conditioner™, as well as the APEX-delfino® Inlet Geometry and Guiding Blades condition the flow distribution for improved operation of our Plate-Type Heat Exchangers. Overall, this technology guarantees proper working conditions and increases the lifetime of the units.