Products

APEX Group offers high quality heat transfer equipment which is custom-designed according to our clients’ process and structural needs. Our patented technologies – created based upon 50+ years of experience in heat transfer – provides APEX Group with the solid technical foundations that enables us to have a strong competitive edge in today’s market.

Heat Exchangers

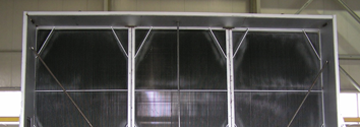

CORPEX®

High performance plate-type heat exchangers for gas-to-gas heat transfer applications.

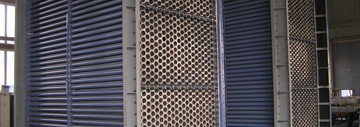

V-FLEX®

Plate-type heat exchangers featuring increased resistance to differential pressure and enhanced heat transfer coefficient.

C-PEX®

Heat exchangers for pressurized fluids on tube-side and gaseous non-pressurized fluids on X-side.

CORTEX®

Tubular non-pressurized heat exchangers.

Key Benefits of APEX Group's Heat Exchangers

- Custom-designed in accordance with the client’s needs

- High thermal effectiveness

- Superior metal temperature control

- Resistant to corrosion

- Wide range of possible construction materials

- Low operating pressure drops

- Easy cleaning

- Low fouling tendency

- Low maintenance costs

- No direct power consumption

- No leakage between streams

- Compact size

- Flexibility in fluid flow arrangement

Operation Unit (Service):

- Air Preheater

- Water Air Preheater

- Steam Air Preheater

- Gas/Gas Heater

- Steam Gas Heater

- Gas/Gas Cooler

- Water Gas Cooler

- Boiler Feedwater Preheater (Economizer)

- Steam Generator

- Glycol Heater

- Thermal Oil Air Preheater

- Thermal Oil Heater

- Flue Gas Condenser

- Blowdown Cooler

Main Applications:

- Fired heaters

- Reformers

- Cracking furnaces

- Industrial boilers

- Power plant boilers

- Gas Turbines

- Incinerators (Thermal Oxidizers)

- Dryers

- DeNOx SCR Units

- Bag filtering systems

- Electrostatic Precipitators

- Flue Gas Desulfurization (FGD)

- Carbon Capture and Storage (CCS)

Main (Sub) Industries:

- Refining & Petrochemical

- Power

- Waste-to-Energy

- Biomass

- Fertilizers

- Pulp & Paper

- Metallurgy

- Flue-Gas Treatment

- Cement

- Food and beverage

- Pharmaceutical

- Chemical